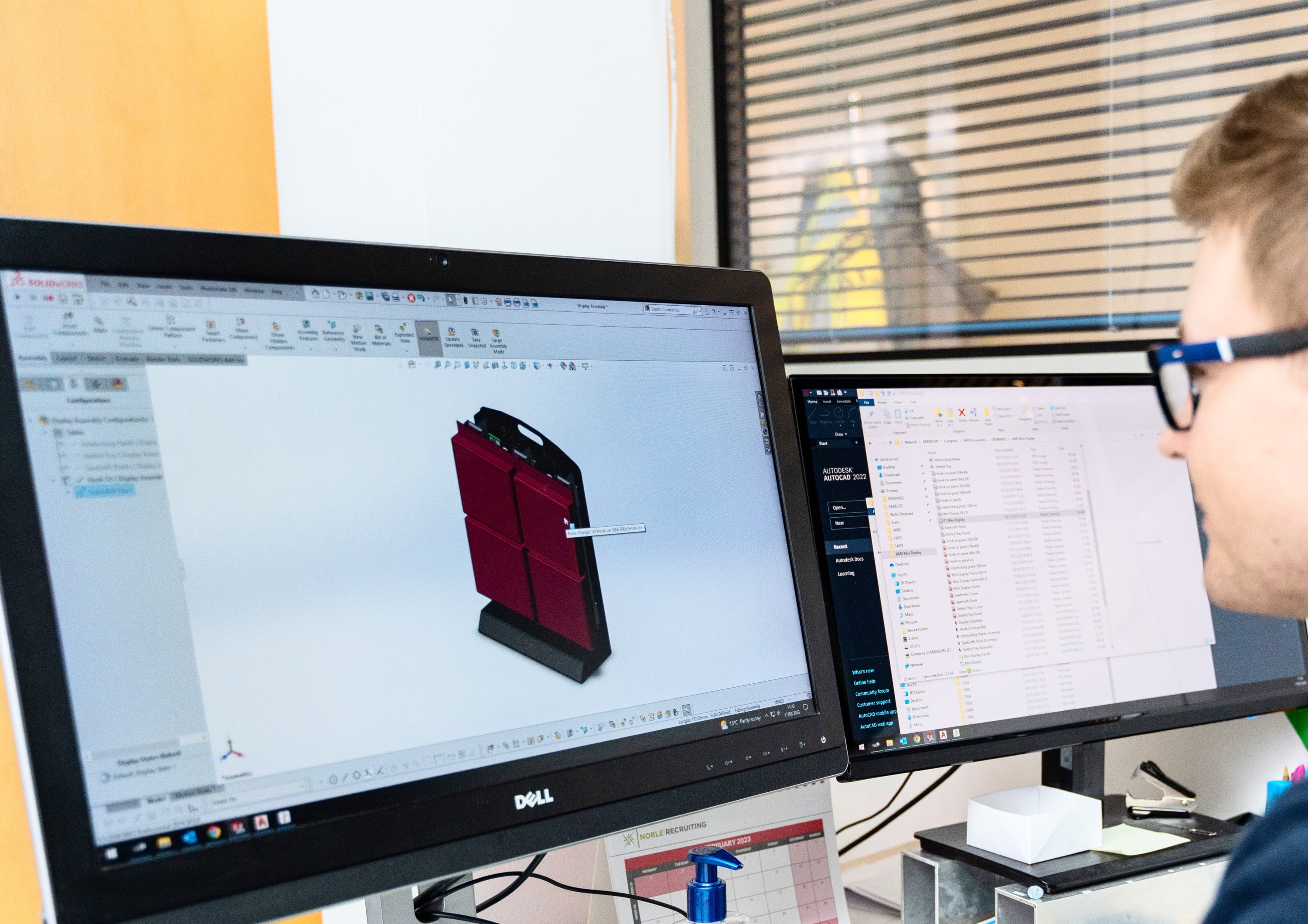

In partnership with specifiers and installers, we design, fabricate and manufacture completely bespoke metal cladding systems. AMS also provide a full metal fabrication service to various other markets UK wide.

About Us

Over the years we have grown to supply a myriad of new-build and renovation or refurbishment building projects throughout London, South East & the UK with a vast range of façade treatments typically specified by architects or contractors.

We’ve grown organically because while we are happy to supply standard solutions what we really relish is a challenge. The more custom the project, the more we rise to that challenge. And we’ve developed solutions to match those aspirations – those of our customers as well as our own.

About Us

Over the years we have grown to supply a myriad of new-build and renovation or refurbishment building projects throughout London, South East and the UK with a vast range of façade treatments typically specified by architects or contractors.

We’ve grown organically because while we are happy to supply standard solutions what we really relish is a challenge. The more custom the project, the more we rise to that challenge. And we’ve developed solutions to match those aspirations – those of our customers as well as our own.